Since the invention of holography by Dennis Gabor in 1947, the technology for generating spatial images has evolved considerably. However, there are still some limitations in spatial resolution and possible viewing angle. The use of modern nanotechnology can, however, remove some restrictions and realize novel encoding methods for ultrathin holograms by using modern nanotechnology.

Holography makes it possible to reproduce spatial information, such as the depth of an object or different angles of view. Even if it is just a picture, this can be perceived by us as very real because of its spatiality. In simple photos, only the reflected light intensity of the object is recorded. Holography must also record the phase of the lightwave emanating from a particular point. This information is stored in the actual hologram (for example, a kind of photo plate) and read out again by illumination with a suitable light wave. The light wave is modified in such a way that the impression is created that it was reflected by the original object.

Holograms are nowadays usually calculated with the help of a computer for a specific object and then realized with so-called spatial light modulators. This technique is used in a modified form in the widespread video projectors. The phase information of the light wave is thereby recovered locally in individual pixels on the spatial light modulator. However, the size of these pixels is limited for technical reasons in the range of at least a few micrometers and is thus significantly larger than the wavelength of visible light used (0.4 to 0.8 microns). Since the pixels are assembled into a periodic array, this results in diffraction effects that significantly limit the viewing angle of the generated image and at the same time limit the resolution, especially for small holograms.

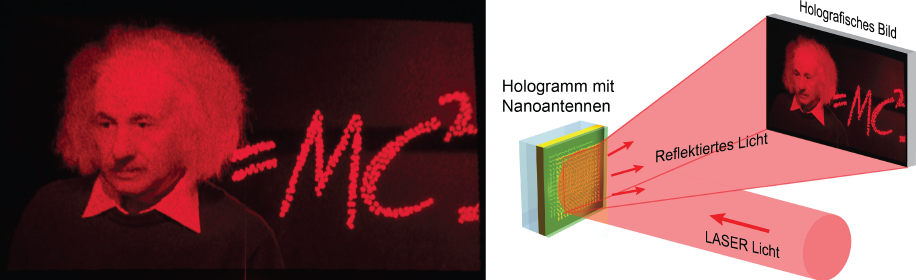

In our research, we use nanoscopically small metal and dielectric structures for holographic concepts. It is of great advantage that the pixel size can be smaller by at least an order of magnitude and thus circumvent the described diffraction effects. In our group, we use so-called meta-surfaces for the production of holograms. These consist of a periodic arrangement of small metallic or dielectric nanostructures. The light can be picked up and emitted by these nanostructures for a short time. If such a structure is illuminated with circularly polarized light, the re-emitted light acquires a phase delay, which depends only on the orientation of the nanostructure. In addition, the polarization state of the light changes, for example from right to left circular.

This effect of phase delay can be used to create a spatial phase distribution along a surface. On the computer, the corresponding phase distribution can be calculated for a specific object and translated into an orientation of the nanostructures. The small structures are produced by means of electron beam lithography on a carrier material (for example glass). This creates the actual hologram that is extremely thin with a high pixel density.

If the hologram is illuminated with light, its phase is locally delayed differently as it passes through the hologram - just as if the light were reflected by the original object. The observer thus receives the impression, e.g. to look at a three-dimensional object.

The creation of holographic images and holographic beamforming will play an increasingly important role in many future applications. The use of modern nanotechnology can help overcome some of the problems of classical holography. In the future, it may be possible to use this technique to produce high-resolution holograms that allow for a significantly extended viewing angle or operate over a very broad spectral range.